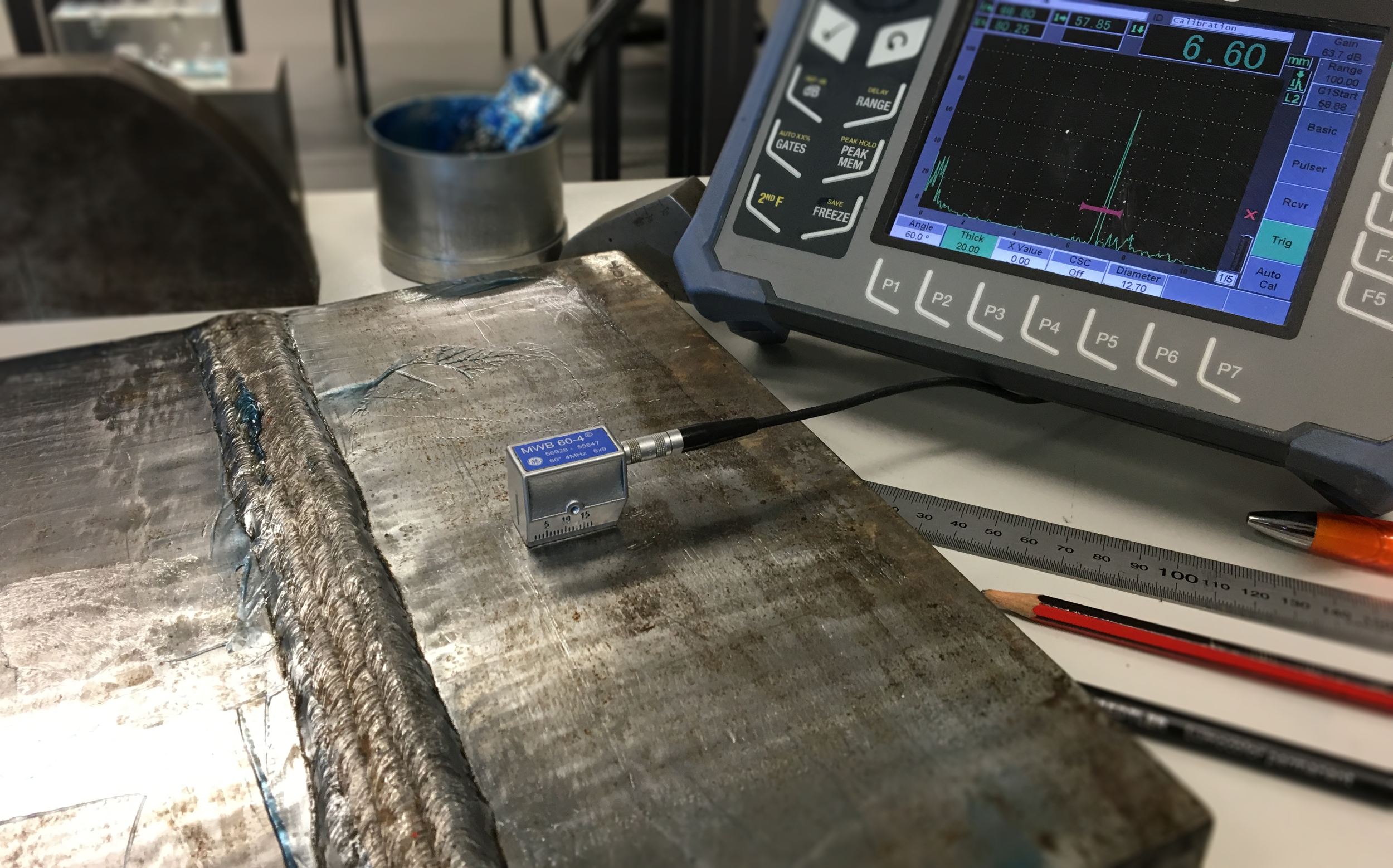

Ultrasonic Acoustic Emission Testing

Pneumatic valves and compressed air/gas supply systems are analyzed for Leakages through non-contact leakage detection procedure by utilizing an ultrasonic acoustic signal analyzer. Furthermore, a contact module enables the instrument to measure performance drops in the steam traps and valves

For those plant maintenance professionals looking for fully featured ultrasound inspection services that provide them with the capability of testing, analyzing and reporting their results quickly, easily and efficiently. Perfect for diagnoses early stage errors and lubrication services.

For detection and analysis of following failure modes

On Board Analysis of Mechanical Inspection/Trending

• Bearing Conditions

• Rubbing Conditions

• Cavitations

• Gears/Gear Boxes

• Pumps/Motors

• Lack of Lubrication/Over Lubrication

On Board Analysis of Electrical Inspection

• Arcing

• Tracking

• Corona

For use in these application

• Switchgear

• Transformers

• Insulators

• Relays Bus Bars