Piping and Stres Analysis

"Identify and eliminate Flow induced vibrations (FIV's) - based pulsations andfatigue in piping system with IMMUSCO"

FIVis, because of turbulent flow conditions, are the major cause for undesirable pulsations in pipelines which initiate low cycle fatigue (L.Cn phenomenon Consequently,

pipeline systems deteriorate with the passage of time and ultimately resulting in crack initiation j propagation and inappropriate pipelines support.

IMMUSCO's specialists can provide the following services by taking measurements on your existing piping system and determine its health condition

Pipe vibration analysis

• Natural mechanical response analysis

• Forced induced vibration (FIV) analysis

• Critical frequency range identification

• COS (Operational Deflection Shape

State of the Art Technologies

Portable Performance Analyzer

• 4-ch, pulsation analysis

• 4-ch, piping vibration analysis

• n 4-ch, dynamic flow analysis

• Reciprocating compressor and engine

Portable Vibration Analyzer

• Resonance / Modal analysis

• Dynamic analysis of

• 4-ch, piping vibration analysis

• Foundation and structure

Multi-Channel Analyzer

• Simulating Software

• Resonance / Modal analysis

Simulating Software

• Operating deflection shape

• Vibro-acoustic analysis

• (ODS) analysis

• Structural dynamics & simulation

• Modal analysis

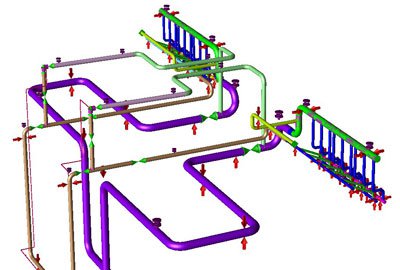

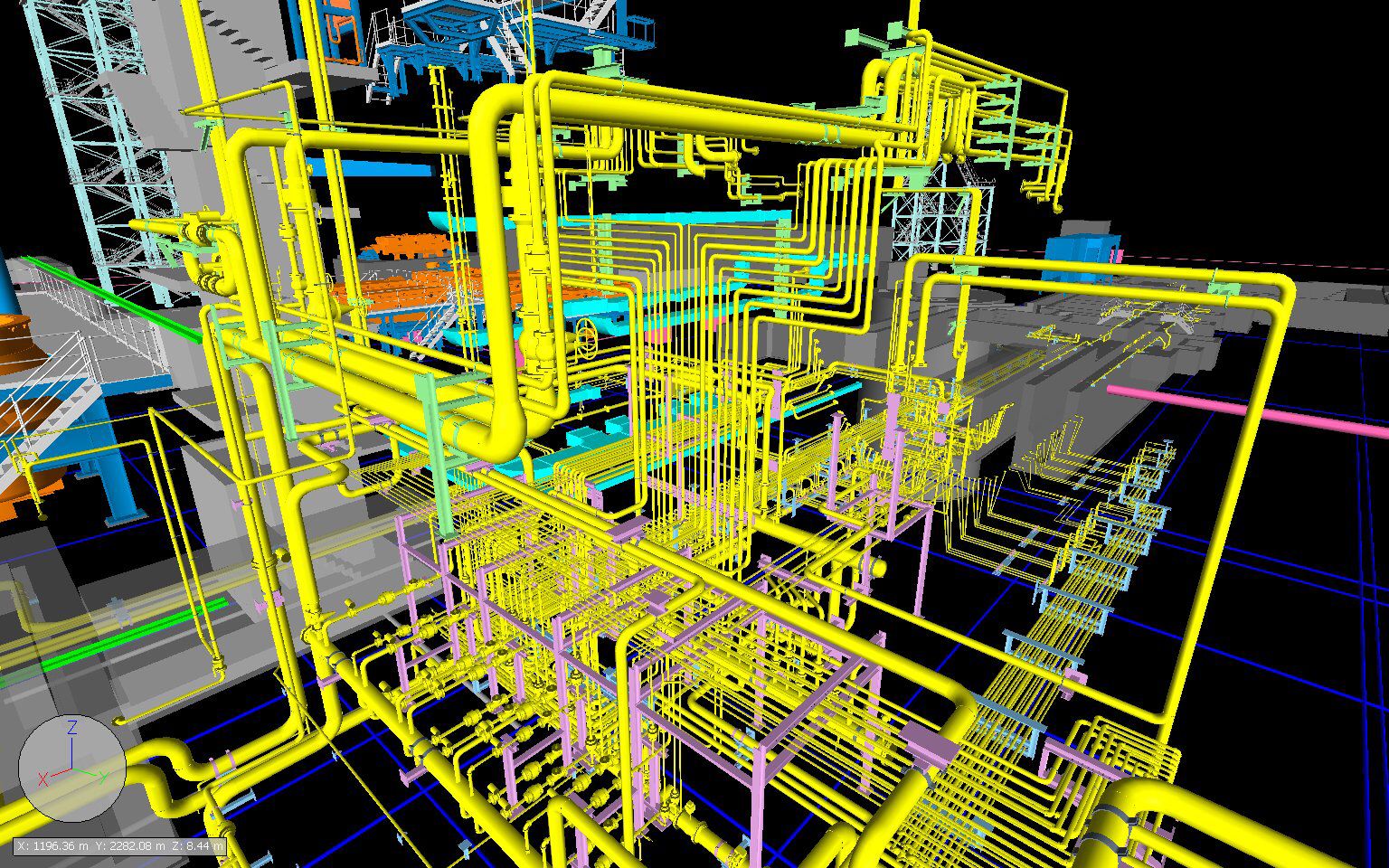

Process Overview

1. Sensors are temporarily mounted, dynamic pressures are recorded, and vibration amplitude/ phase measurements are noted at multiple locations of pipeline system.

2. Operating Deflection Shape (OW analysis is then performed by 3D-Modelling of pipeline systems in ODS software.

3. A comprehensive report is generated, including 3D animations to visualize the system's mechanical behavior along with the guideline on how to improve the piping system's integrity. (e.g. Locations to add or replace piping supports, or any alterations required in the pumps/compressors' operating parameters, etc.)

Your Problem

Cannot verify if the pipe supports added are adequate for long term integrity. Cannot identify the unsafe operating ranges of your compressors or pumps, which negatively affect the life of adjacent pipe cork.

Our Solution

Instead of trying to suppress vibration magnitude by simply adding or replacing pipe supports at random locations, it is important to eliminate the cause. Our experts will analyze your piping system and advice on how to move the forcing vibration frequencies to the safe zone. IMMUSCO can identify the vibration resonance range in which your pipevvork's natural frequencies coincide with the nearby forcing frequencies and accordingly recommend which operating ranges of your reciprocating compressor or pump should be avoided. IMMUSCO can not only measure steady vibration characteristics of your pi pework but also record continuous data for extended periods which allows analysis of transient events such as water hammer and other momentary surges.