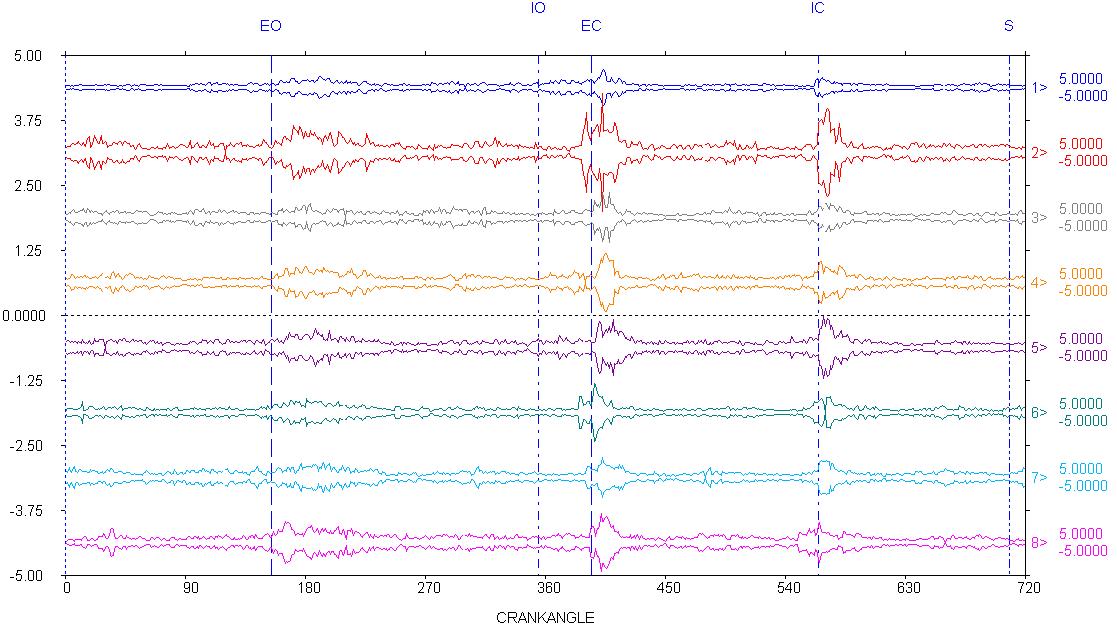

Engine Inspection using Windrock Technology

Diagnostics:

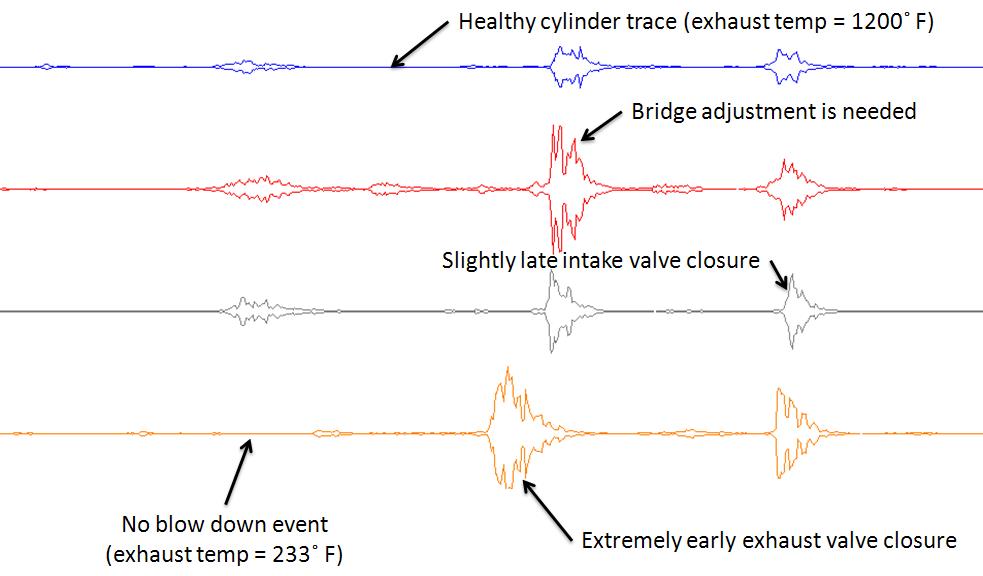

Following diagnostics will be performed on Engine by using Windrock 6320 Analyzer: • Leaking valves and rings, Worn or Scored Liners • Defective Fuel Injection valves • Ignition System deficiencies • Intake/Exhaust Port or Bridge Wear • Worn or defective valve train Components • Turbo charger Defects • Damaged Bearings Identifications • Damaged Connecting Rods and wrist pins • Jacket Water and lube oil pump faults • Excessive Frame Vibration • Foundation or Grout Damage • Engine Oil Test • Peak Firing Pressure Imbalance (If Pressure Indicators Kiene valves are available) • Horsepower Discrepancies (If Pressure Indicators Kiene valves are available) • Infrared Temperature Readings of each cylinders

PURPOSE:

The purpose of Windrock inspection includes, • Evaluate performance • Maximize Machine Efficiency • Maximize Valve Life • Maximize Throughput to Horsepower Ratio • Research and Development • Economic Evaluation • Evaluate mechanical condition On-Condition Maintenance • Insure Reliability and Safety • Evaluate PM program • Reduction of Maintenance Costs • Less Downtime and Lost Production • Attempt to “Warrant” no Catastrophic Breakdown between Analyses.

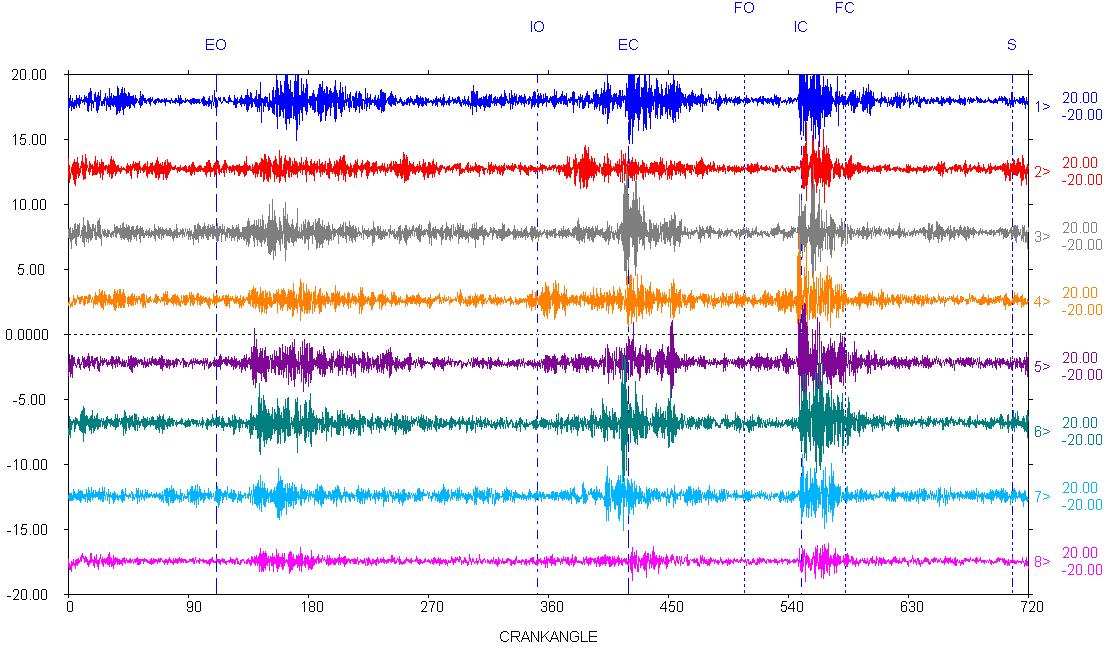

Reciprocating Compressors Inspection using Windrock Technology

Diagnostics:

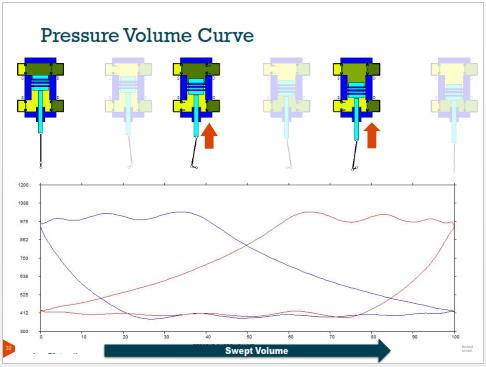

Following diagnostics will be performed on Compressors by using Windrock 6320 Analyzer: • Damaged Bearings Identification • Piston ring/riders condition • Compressor’ Suction and Discharge Valves malfunction • Damaged Connecting Rods and wrist pins • Cross Head and packing defects • Pressure Volume Curves, Flow balance, Performance Report (If Pressure Indicators Kiene valves are available) • Excessive Frame Vibration • Foundation or Grout damage • Infrared Temperature Readings

PURPOSE:

The purpose of Windrock inspection includes, • Evaluate performance • Maximize Machine Efficiency • Maximize Valve Life • Maximize Throughput to Horsepower Ratio • Research and Development • Economic Evaluation • Evaluate mechanical condition On-Condition Maintenance • Insure Reliability and Safety • Evaluate PM program • Reduction of Maintenance Costs • Less Downtime and Lost Production • Attempt to “Warrant” no Catastrophic Breakdown between Analyses