Diagnostics:

Following diagnostics will be performed on Compressors by using

Windrock 6320 Analyzer:

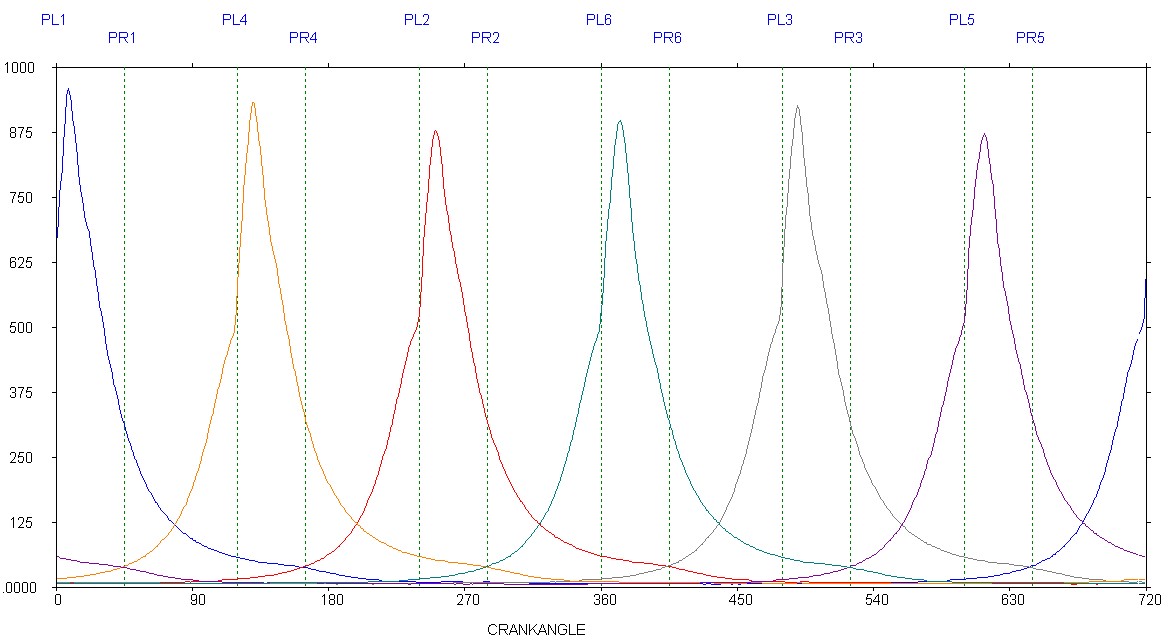

• Damaged Bearings Identification

• Piston ring/riders condition

• Compressor’ Suction and Discharge Valves malfunction

• Damaged Connecting Rods and wrist pins

• Cross Head and packing defects

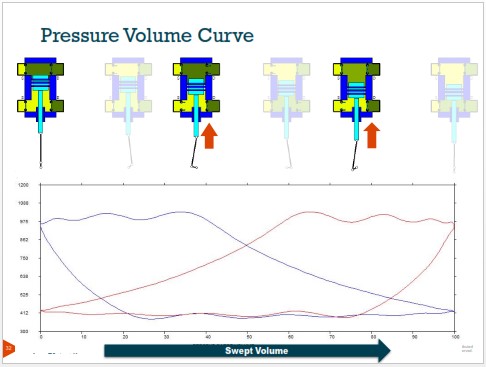

• Pressure Volume Curves, Flow balance, Performance Report (If

Pressure Indicators Kiene valves are available)

• Excessive Frame Vibration

• Foundation or Grout damage

• Infrared Temperature Readings

PURPOSE:

The purpose of Windrock inspection

includes,

• Evaluate performance

• Maximize Machine Efficiency

• Maximize Valve Life

• Maximize Throughput to Horsepower Ratio

• Research and Development

• Economic Evaluation

• Evaluate mechanical condition On-Condition Maintenance

• Insure Reliability and Safety

• Evaluate PM program

• Reduction of Maintenance Costs

• Less Downtime and Lost Production

• Attempt to “Warrant” no Catastrophic Breakdown between

Analyses

Novotest - NDT

Novotest - NDT

HKDQTECH - Thermal Imagers

HKDQTECH - Thermal Imagers

UE Systems - Tools

UE Systems - Tools